When ordering your brake line, you will need to specify the following:

- Material of the brake line – rubber or stainless steel braided (colors available on SS braided)

- Inside diameter of the brake line – 1/8” or 3/8” (read our related blog about advantages of stainless steel braided brake hose and smaller inside diameter brake lines)

- Overall (end-to-end) length of the hose

- Thread size of each hose end (see our related Thread Identification blog)

- Fitting type of each hose end and its clocking

- Any hose brackets and their clocking

- Any desired accessories such as protective springs, strain relievers, abrasion protective sleeves or heat protection sleeves.

Identifying Brake Hose Fittings

Identifying your brake line fittings consists of three steps:

- Identify the thread sizes

- Identify the end configurations

- Identify the fittings group and type

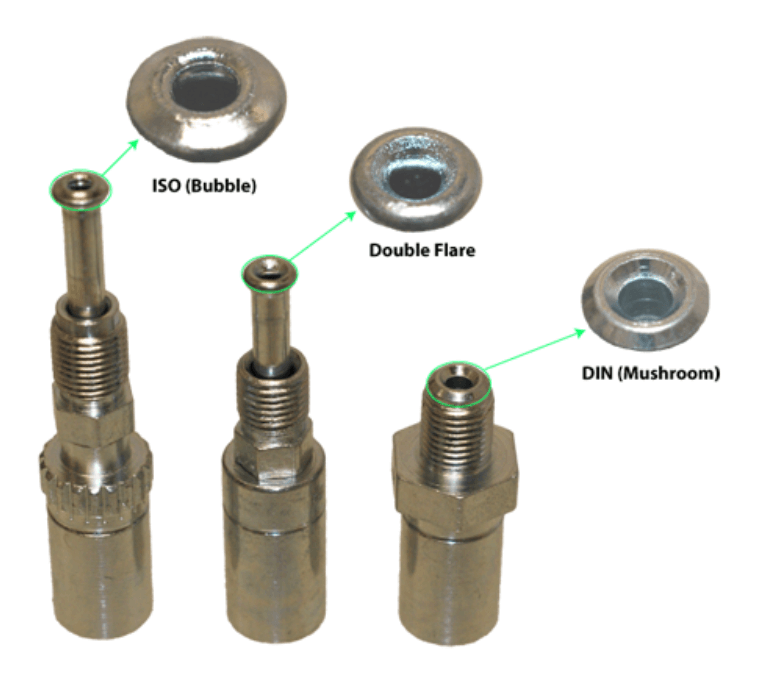

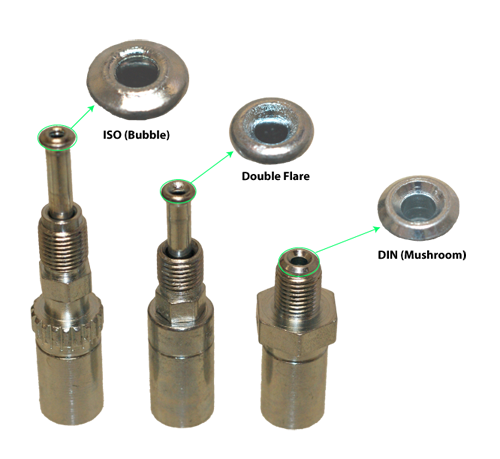

Brake Line Fittings End Configurations:

On rare occasions we come across a pipe thread, but typically brake hose fittings involve a flare. There are three types of flares on brake hose fittings:

ISO Flare (Bubble)

- 45° ISO Flare (also known as bubble flare) – the female seat angle is 96°

Double Flare

- 45° Double Flare – the inverted seat angle is 42°

DIN Flare (Mushroom)

- 31° DIN Flare (also known as mushroom flare) the female seat angle is 120°

Note: The seat angles vary from the tube angles in order to seal the smallest diameter.

Brake Line Fitting Groups:

- Banjo

- Center Support Fitting (bracket)

- Male Fitting

- Female Fitting

- Other/Special Fitting

Banjo Fittings:

- Round Style – Straight

- Round Style – Bent

- Block Style

- Tube Style – Either Side

- Tube Style – Left

- Tube Style – Right

Center Support Fittings

- Clip mount

- Bracket Mount

Male Fittings

- Standard mount

- Bulkhead mount

- Clip mount

Female Fittings

- Clip Mount

- Bolt-On Mount

- Bulkhead Mount

- Bracket Mount

Trust the Experts

There are many situations which could prevent you from correctly identifying parts of your brake hose assembly.

- The brake hose fittings may include long tubes with complex bends, making it hard to measure the brake line's overall length.

- You may not have the necessary tools to accurately measure thread size and pitch – making it easy to confuse metric and imperial threads.

- You may not get the clocking just right.

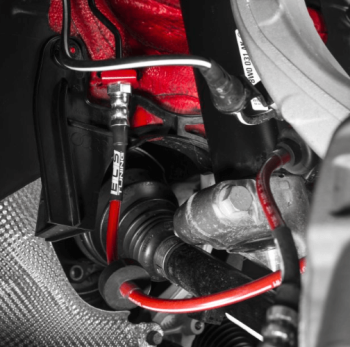

- You may want to make an adjustment to your existing brake line because your vehicle is being modified (lifts, wider axles, aftermarket brakes…).

Whatever the situation, you are always safe bringing your old brake lines to one of Hihydraulic for accurate identification, fabrication, and replacement of old brake lines.